|

|

Wood

Bats 4 Sale

RockBats

RockBat

Composite

Wood and

Maple

Laminated

Baseball Bats |

|

|

|

|

|

|

We sell wood bats and BBCOR.50 composite wood bats

and wood bats at

a fair price, we're not cheap and we're not

expensive.

Our price is just plain fair!

Our service is our pledge, we ship USPS

Priority Mail (2 day), and we want your

friends to order. |

|

|

|

|

|

More BBCOR.50 Bats for sale in the next few

weeks see

woodbats4sale for now. |

|

|

|

Bat shape. All of our Rock Bat models

that are available in solid-wood are now available in our all-wood

laminated composite design. If you feel that you can swing a big-barrel

bat with little drop in bat speed, then you can go for that "extra"

performance by trying our model RB 174C. This has the largest barrel

diameter, and if you are a strong player, and can swing this just as

fast... then you will get maximum performance out of this bat model.

NOTE: due to the thin-handle design, we only offer this bat model in

our laminated composite version - because it has HICKORY in the handle

of the bat.

Bat speed. we inserted an extra

lightweight wood in the core of our maple barrel, which reduces the

overall weight, and shifts the balance of the bat toward the hands

(yes, this is like a corked bat). We also inserted an extra-strong,

high-density wood in the core of our maple handle, which further shifts

balance toward the hands. The result: an engineered bat that will

provide more bat speed than a solid-wood bat having the same shape and

weight.

Material properties.To a lesser extent

than bat speed, the material properties that you put into a bat are

important. If you make a bat with high-stiffness wood, you will achieve

better performance (i.e. faster ball speed) compared to the same bat

with "average" wood in the handle. Too much flex in the handle is lost

energy - energy that could have bee transferred to the ball.

NOTE: Our RockBats are manufactured

using ALL-WOOD components. RockBats does not use fiberglass wraps,

fiber-reinforced plastic handles, or internal metal rods.

Tiger Stick Bat Grip

Be ready for Spring Baseball

order your

RockBat

Composite

Wood

Laminated

Baseball Bat

Today |

|

|

|

|

|

RockBat Wood

Laminated

Composite Design |

|

|

|

|

LRB-271

Rock Bat Wood

laminated composite design |

LRB-331Rock

Bat Wood

laminated composite design |

|

|

|

|

LRB-243

Rock Bat Wood

laminated composite design |

LRB-174

Rock Bat Wood

laminated composite design |

|

|

|

The First Angled-Knob Bat Ever Used in an MLB Game Goes to Cooperstown.

Pro XR Ergonomic Bat, U.S. Patent 7,744,497

ST. LOUIS (Oct. 13, 2011) – Two baseball bats featuring an ergonomically

correct angled knob were recently accepted into The National Baseball Hall

of Fame. The bats were first used in an official MLB competition on Sept. 5,

2010 by then New York Mets infielder, Mike Hessman, who hit a double to the

left field wall at Wrigley Field in a game against the Chicago Cubs.

“I’m shocked and excited. It’s a blessing to be part of history. I’m glad I

decided to use it that day,” said Hessman after learning of the significance

of his stand-up double with the new ProXR design. “The bat felt great in the

game. You always feel better when the bat feels good in your hand,” said

Hessman. Five days after Hessman’s hit, Milwaukee Brewers’ Prince Fielder

successfully used the same ProXR angled knob technology in a series of

games.

St. Louis-based designer and inventor Grady Phelan developed the patented

ProXR™ angled-knob bat technology to improve grip, performance and bat

speed. “Seeing Mike Hessman hit a double with my ProXR bat was tremendous

validation for this new design. Having that bat accepted into the Baseball

Hall of Fame is a huge honor,” said Phelan. |

|

|

|

Fungo Bat

Fungo bats are specially designed for

fielding practice and/or training. The 35" fungo is typically used by

coaches for hitting fly balls to outfielders.

Every RockBat Fungo has the Major League ink spot on the handle and the

sweet spot identification on the barrel. Coaches can utilize these features

as an excellent teaching tool when discussing wood bats with young players.

Order your Rock Bat Wood

Composite |

|

|

Be ready for Spring Baseball order

your Rock Bat

| |

RB

243 |

RB

271 |

RB

331 |

RB

174 |

|

Bat Design |

Balanced

Large barrel

Thick handle |

Balanced

Medium barrel

Medium handle |

Super-Balanced

Medium barrel

Medium handle |

End-weighted

XL barrel

Thin handle |

|

Knob Design |

Medium Knob

Moderate flare |

Medium Knob

Moderate flare |

XL Knob

Large flare |

Medium Knob

Light flare |

|

Taper Design |

Fast Taper |

Long, Slow Taper |

Moderate Taper |

Fast Taper |

|

Species |

Hard Maple |

Hard Maple |

Hard Maple |

Hard Maple |

|

Barrel Size |

Large |

Medium |

Medium |

Large |

|

Handle Size |

Thick |

Medium |

Medium |

Thin |

|

Comparable Model |

M110/C243 |

C271 |

C331 |

G174 |

|

Lengths |

32", 33", 34" |

32", 33", 34" |

32", 33", 34" |

33", 34" |

|

Weight Drops |

-3 |

-3 |

-3 |

-2 |

|

Barrel Cup |

Yes |

Yes |

Yes |

Yes |

|

About RockBats

Be sure to visit our other informational site:

http://www.woodbat.org/

Where you can learn more about wood quality and wood

baseball bats

Our Background

You've probably read all the stories

about former players, former carpenters,

former bat reps, or even former sawmills

deciding to start their own maple baseball

bat business. At RockBats, we have a

different story to tell.

RockBats was founded by Roland Hernandez -

a Research Wood Scientist from the USDA

Forest Products Laboratory - the national

research laboratory of the Forest Service

located in Madison, Wisconsin. Read more

about the Forest Products Laboratory at

their

website.

RockBats was founded by Roland Hernandez -

a Research Wood Scientist from the USDA

Forest Products Laboratory - the national

research laboratory of the Forest Service

located in Madison, Wisconsin. Read more

about the Forest Products Laboratory at

their

website.

For over 17 years, Roland was a government

researcher in the area of structural

engineered wood products - primarily

glued-laminated timber. His research

involved (1) Utilization, (2) Analysis, and

(3) Optimization of wood materials for the

development of viable structural wood

products. One utilization project involved

taking small-diameter Ponderosa pine forest

thinnings and making usable structural

glued-laminated timber beams (click here to

read that Forest Service report). Analysis

projects involved interpreting laboratory

test data, developing computer simulation

models, and formulating reports and

recommendations that could be implemented

by the structural wood products industry.

Optimization projects were the culmination

of years of research - resulting in

IMPROVED performance of structural wood

products.

In one particular project, a

high-performance glulam beam was designed

and tested in the laboratory

(click here to see that Forest Service

report). That technology was used by

Anthony Forest Products to create what is

now called the "Power Beam"

(see here). To this day, this is still

the strongest all-wood glulam beam

available in the wood products industry.

In one particular project, a

high-performance glulam beam was designed

and tested in the laboratory

(click here to see that Forest Service

report). That technology was used by

Anthony Forest Products to create what is

now called the "Power Beam"

(see here). To this day, this is still

the strongest all-wood glulam beam

available in the wood products industry.

In addition to the 50+ research reports,

Roland has authored several chapters in

various Wood Engineering textbooks - Glued

Structural Members chapter in the Forest

Service Wood Handbook (2000 version), Wood

Properties section in Mark's Handbook for

Mechanical Engineers, and others.

Then came baseball bats

Having always been a baseball fan, the

idea of applying his wood science and

engineering background to baseball bats has

always been intriguing. It was about 2000,

when he decided to begin a business

relating to wood baseball bats. However,

rather than diving in with a lathe and some

wood blanks, he decided to research what

had been done for the past 100 years. Here

is where his background in (1) Utilization,

(2) Analysis, and (3) Optimization came in

handy.

First of all, it was well known that the

most common wood to use was White ash (Fraxinus

americana), a strong wood that has good

resistance to impact strength, and is the

correct density to make desirable weight

baseball bats. Ash has good wood

properties, so it was no surprise that this

was the most popular baseball bat wood in

the past 100 years. Also well known was

that players are supposed to hit "LOGO UP"

with an Ash bat, so that ball contact is

made on the edge-grain. Players knew that

they had to hit on the edge grain to

prevent "flaking". Flaking occurs on Ash

because it is a ring porous species -

repeated contact on the flat-grain results

in the annual rings separating, as shown in

the photo on the right.

First of all, it was well known that the

most common wood to use was White ash (Fraxinus

americana), a strong wood that has good

resistance to impact strength, and is the

correct density to make desirable weight

baseball bats. Ash has good wood

properties, so it was no surprise that this

was the most popular baseball bat wood in

the past 100 years. Also well known was

that players are supposed to hit "LOGO UP"

with an Ash bat, so that ball contact is

made on the edge-grain. Players knew that

they had to hit on the edge grain to

prevent "flaking". Flaking occurs on Ash

because it is a ring porous species -

repeated contact on the flat-grain results

in the annual rings separating, as shown in

the photo on the right.

Another intriguing rule-of-thumb was the

practice of selecting Ash bats that had

approximately 8 to 10 rings per inch. It

was known that bats with these number of

"grains" were stronger than other bats.

Well, through independent research - and

having the convenience of working at the

national laboratory of the Forest Service,

Roland dug up data that showed WHY it is

desirable to select Ash bats having 8 to 10

rings per inch.

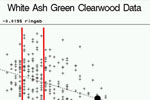

The graph shows rings per inch on the

x-axis versus stiffness of White ash on the

y-axis. This is data on wood blanks that

were tested prior to the 1930's. Note that

as the rings per inch increases, the

stiffness of the tested wood drops. The red

lines show a range of approx. 8 to 12 rings

per inch, and the large dot is centered at

25 rings per inch. There is about a 20%

drop between the data within the red lines,

and the large dot at 25 rings per inch. The

graph for strength shows a similar trend.

The graph shows rings per inch on the

x-axis versus stiffness of White ash on the

y-axis. This is data on wood blanks that

were tested prior to the 1930's. Note that

as the rings per inch increases, the

stiffness of the tested wood drops. The red

lines show a range of approx. 8 to 12 rings

per inch, and the large dot is centered at

25 rings per inch. There is about a 20%

drop between the data within the red lines,

and the large dot at 25 rings per inch. The

graph for strength shows a similar trend.

So, this data shows that the 100-year-old

rule-of-thumb was pretty accurate...

players WILL get good wood if they pick an

Ash bat with approx. 8 to 10 rings per

inch. However, note that this range could

be expanded out to perhaps 8 to 12 rings

per inch.

One new question arose; if ring-porous Ash

bats need to be hit on the edge grain

because the annual rings will "flake" if

hit repeatedly on the flat-grain... then

what about Maple bats? Maple is not a

ring-porous species, it is a diffuse porous

species. "Diffuse-porous" means that there

are NO porous wood layers in each year of

growth. So the question now was, do Maple

bats NEED to be hit on the edge grain? The

answer is NO.

This brings up the next logical question -

if Maple bats do NOT NEED to be hit on the

edge grain, then what would be the

preferred orientation? Again, through

independent research - and the convenience

of working at the national laboratory of

the Forest Service, Roland dug up data that

showed which ORIENTATION is the strongest

when testing wood blanks.

In the 1960s, several species of wood were

tested for toughness (which is similar to

impact bending - like a "karate chop"

test). This was just a basic research

report, but it was perfectly tailored for

wood baseball bats... and was resurrected

by Roland over 40 years later. In that

report, results were convincing that wood

is stronger when contact is made on the

flat grain.

This is even true for Ash. So, the Ash

handle of a baseball bat is stronger when

impact is made on the flat-grain of the

barrel. BUT, edge-grain contact is still

advocated for Ash because the annual rings

in the barrel will fatigue and separate

after repeated hits.

Even MORE INTRIGUING with the data shown in

this chart is that rupture on the bark side

of the wood is stronger than on the

opposite face.

Because of this independent research,

RockBats WAS THE FIRST WOOD BAT COMPANY

THAT ADVOCATED THAT MAPLE BATS BE ORIENTED

FOR FLAT-GRAIN CONTACT... this was 2005.

Because of this independent research,

RockBats WAS THE FIRST WOOD BAT COMPANY

THAT ADVOCATED THAT MAPLE BATS BE ORIENTED

FOR FLAT-GRAIN CONTACT... this was 2005.

Maple bats became popular starting in the

mid-1990's, yet every single bat company

that made maple bats during those years was

placing their logo on the flat-grain, and

advocating edge-grain contact - same as had

been done for 100 years with Ash bats.

No one stopped to asked the question - "I'm

using a different wood, should I be doing

something different?"

If you have wondered, "should I still pick

8 to 12 rings per inch for Maple?" The

answer is NO.

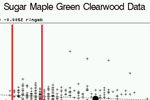

That same data for rings per inch was also

available for Maple, and the data shows

that there is NO considerable drop in

stiffness (and strength).

In the data for Maple, that large dot that

sits on the average line at 25 rings per

inch shows that stiffness has less than a

5% drop, compared to the average stiffness

between 8 to 12 rings per inch.

In the data for Maple, that large dot that

sits on the average line at 25 rings per

inch shows that stiffness has less than a

5% drop, compared to the average stiffness

between 8 to 12 rings per inch.

In short, you DON'T NEED TO COUNT YOUR

RINGS ON A MAPLE BAT.

Then came the wood grading

Having worked with the structural

engineered wood products industry, Roland

was deeply involved in the development of

standards and design methodologies for

these wood products. It was a NECESSITY...

these wood products hold up the roof over

our head, so it was important to DESIGN

these wood products to withstand design

loads - and it was important to use

correctly graded lumber to make these

structural wood products.

In the wood bat industry, there were NO

standards for the wood used to make the

bats - not even at the highest level of

game play. So, Roland set out to develop a

wood grading standard of his own - this was

2002.

Wood bats don't have knots, so a wood

grading standard for bat blanks was not

going to be like a structural lumber

standard - which limits the size and

occurrence of knots on the board. A grading

standard for wood bat blanks was going to

be based on grading clear wood... and the

#1 factor that controls the strength of

clear wood is a property called

"slope-of-grain". Basically,

"slope-of-grain" is the angle at which a

piece of wood is cut, relative to the grain

direction growing in the log. For over 100

years, logs were SPLIT to make the staves

that became bat blanks. This was the best

method to consistently produce

straight-grained bat blanks - because split

blanks followed the grain, and this

resulted in baseball bats with

straight-grain.

Maple logs, however, do not split very well

- so these are often sawn at a sawmill.

When you saw a log, you are not following

the grain 100% like when you split a log.

Therefore, wood blanks that are sawn can

have a "slope" to the grain. It is this

"slope" that needs to be controlled,

otherwise, the strength of the baseball bat

is severely reduced.

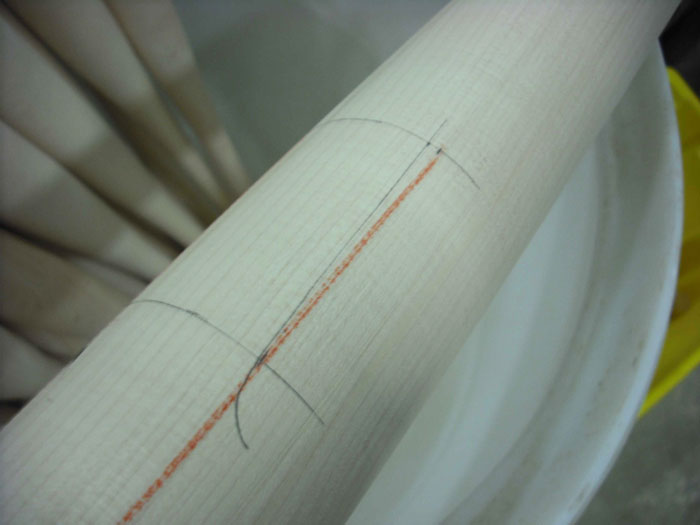

Here are two photos showing the edge grain

(left) and the flat grain (right). The

edge-grain straightness has been graded for

the past 100 years... the straighter the

grain, the stronger the bat. What was NOT

graded for straight grain was the flat

grain face. For Ash wood that had been

split, this was not a problem - because

those blanks had straight-grain due to the

splitting process. But when maple blanks

are SAWN from log, the "slope of grain" on

the flat-grain face is the one that went

unnoticed.

Here are two photos showing the edge grain

(left) and the flat grain (right). The

edge-grain straightness has been graded for

the past 100 years... the straighter the

grain, the stronger the bat. What was NOT

graded for straight grain was the flat

grain face. For Ash wood that had been

split, this was not a problem - because

those blanks had straight-grain due to the

splitting process. But when maple blanks

are SAWN from log, the "slope of grain" on

the flat-grain face is the one that went

unnoticed.

Need to clarify, by SAWING maple logs, you

can still produce top-quality maple blanks

for baseball bats. BUT, you have to apply

additional steps in your processing, which

for Ash - was being taken care of by

splitting the logs. If you are a sawmill

and plan to produce maple blanks, you will

need to grade your planks and cut WITH THE

GRAIN.

Three wood science facts made this

"slope-of-grain" situation escalate into

the broken bat problem often associated

with Maple bats... (1) maple was not

typically split from logs, so this meant

that a significant slope-of-grain could

exist on the flat-grain, (2) wood is

WEAKEST in the plane perpendicular to the

rings, and (3) the impact bending strength

of wood drops dramatically as the angle

from straight-grain increases.

- The photo in the above right shows an

ink spot that bleeds along the grain, and

the red line is the center line that is

down the middle of the round blank.

Because this wood blank was sawn from a

log, there was a slight angle between the

straight piece of wood and the wood grain

within it - this is called

"slope-of-grain" on the flat-grain face.

- When wood failure occurs, it is

usually along the radial planes of the

log - perpendicular to the flat-grain

face. Imagine how you would split a log

of firewood - you split it into "pie"

wedges, because those radial planes are

the WEAKEST planes. When a wood bat

splits apart like in the photo on the

right, it usually splits along the radial

planes - they do NOT break by the annual

rings separating from each other. This is

very important to understand!

- As the "slope-of-grain" increases, it

severely drops the strength of the bat.

Also, bats that break due to a high

"slope-of-grain" will have the classic

OVAL-SHAPED break like that shown at

right. Bats that have perfect

straight-grained wood do NOT break like

that shown at right.

Why did Maple bats develop into a

problematic "broken bat" issue?

Bats do not break by "slope-of-grain"

because they are Maple, bats break by that

oval-shaped "slope-of-grain" break because

they have a severe angle of grain, with

respect to the centerline of the bat. You

could point to the fact that maple logs

don't split very well (lots of waste), so

manufacturers of bat blanks need to saw the

logs into blanks. Sawing doesn't

"automatically" follow the grain like

splitting does - so if a sawmill doesn't

take care to follow the grain, they will

produce blanks with severe slope-of-grain.

Furthermore, there were no grading rules

that bat makers could follow - so when

purchasing wood blanks to make baseball

bats, they were simply buying CLEAR WOOD

(no knots) and that's it. Lumber grading

standards were based on making furniture,

and the highest grade for furniture was a

CLEAR piece of wood that had no knots.

Further grading CLEAR WOOD for

straight-grain was unheard of.

So, in 2002, Roland developed a wood

grading standard for his own RockBats that

was going to target a limit for

slope-of-grain in wood bats. The core

technology for this system was based on a

relationship called the Hankinson formula.

It was well established in the wood science

industry that the properties of wood

significantly dropped as the angle of grain

changed.

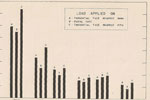

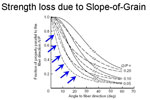

The graph here shows the Hankinson

relationship for several wood properties,

and the impact bending graph is

highlighted. Note that at a 10-degree

angle, the impact bending strength of wood

is only about 35% of the strength of

perfectly straight-grained wood.

The graph here shows the Hankinson

relationship for several wood properties,

and the impact bending graph is

highlighted. Note that at a 10-degree

angle, the impact bending strength of wood

is only about 35% of the strength of

perfectly straight-grained wood.

When sawing logs to obtain maximum yields,

10-degrees is not that unusual of a result

to have in a CLEAR WOOD blank processed

this way.

What level did RockBats choose when

creating their grading standard in 2002?

We wanted an "A+" grade for our RockBats,

so we chose the point of 90% strength on

the Hankinson chart. This is approximately

a 2-degree angle for slope-of-grain.

More intriguing technology

With the wood science established, now

came the engineering that went into the

development of the first RockBats in 2002.

Every ball player knows that a bat has a "sweet

spot", that's the optimum point to make

contact with the baseball. But, where is

the sweet spot? and how do you determine

it's location. Well, by the application of

engineering and physics, RockBats were

developed so that we are the only baseball

bat company to test and identify the

location of the sweet spot on the barrel.

We now had 3 technologies that we believed

would make us the premier wood bat in the

industry: (1) slope-of-grain grading, (2)

flat-grain contact, and (3) sweet spot

testing and identification.

We now had 3 technologies that we believed

would make us the premier wood bat in the

industry: (1) slope-of-grain grading, (2)

flat-grain contact, and (3) sweet spot

testing and identification.

Finally, someone with a wood science and

engineering background stopped to ask the

question... "what's the best way to design

and manufacture a MAPLE baseball bat?".

Our Growth

As is the case with all companies, when

you grow, you cannot do it alone. Our

ownership group expanded from just Roland

and his wife, Elaine - to a well rounded

group of owners that each brought specific

skills to the company.

Ben, Mike, and Charlie Zelazoski, of

Zelazoski Wood Products, Inc. in Antigo, WI

are now part owners of RockBats, LLC. This

family-owned wood products manufacturing

facility was founded in 1924 specializing

in brush and broom blocks. When first

contacted by RockBats, there was one copy

lathe - and today, there are 3 lathes (one

with CNC technology). As you can see by the

photo, turning a piece of wood is only a

small facet of what we can do. With the

expertise in manufacturing, RockBats

correctly approached the baseball bat

business using wood science, and

state-of-the-art manufacturing.

Ben, Mike, and Charlie Zelazoski, of

Zelazoski Wood Products, Inc. in Antigo, WI

are now part owners of RockBats, LLC. This

family-owned wood products manufacturing

facility was founded in 1924 specializing

in brush and broom blocks. When first

contacted by RockBats, there was one copy

lathe - and today, there are 3 lathes (one

with CNC technology). As you can see by the

photo, turning a piece of wood is only a

small facet of what we can do. With the

expertise in manufacturing, RockBats

correctly approached the baseball bat

business using wood science, and

state-of-the-art manufacturing.

Mike and Christy Kingery came on board as

the Major League connection. Mike had 17

years of professional baseball experience

as an outfielder with the Kansas City

Royals, Seattle Mariners, San Francisco

Giants, Oakland A's, Colorado Rockies and

Pittsburgh Pirates. Upon retiring as a

Major League player, Mike returned to his

hometown and created Solid Foundation

Baseball School, Inc. to answer strong

demand from local baseball teams and

players. Mike has trained professional

baseball instructors using hands-on

instruction techniques he learned in the

big leagues, helping players maximize their

abilities and understand the basic

fundamentals of the game. When RockBats

develops a new baseball bat design, all

prototype bats are placed in Mike's hands

to be evaluated for its performance and

feel.

Mike and Christy Kingery came on board as

the Major League connection. Mike had 17

years of professional baseball experience

as an outfielder with the Kansas City

Royals, Seattle Mariners, San Francisco

Giants, Oakland A's, Colorado Rockies and

Pittsburgh Pirates. Upon retiring as a

Major League player, Mike returned to his

hometown and created Solid Foundation

Baseball School, Inc. to answer strong

demand from local baseball teams and

players. Mike has trained professional

baseball instructors using hands-on

instruction techniques he learned in the

big leagues, helping players maximize their

abilities and understand the basic

fundamentals of the game. When RockBats

develops a new baseball bat design, all

prototype bats are placed in Mike's hands

to be evaluated for its performance and

feel.

Dave Bruns and Chuck Steinhauer. Dave Bruns

joined the RockBats group as the veteran

sales professional who will be handling all

retail Dealers and expansion of RockBats

into YOUR neighborhood sporting goods

store. Dave has been an executive at many

levels. His sales and leadership experience

includes time with Procter & Gamble and

Memorex-Telex, among others. Chuck

Steinhauer is the business professional who

is assisting RockBats with our expected

exponential growth in the coming years.

Chuck credits his ability to help

busiensses survive and compete in today's

market by "being on the technological edge

and running an efficient operation".

2007 Season

After 17 years, Roland decided to leave

his government job and pursue running his

business full time - RockBats. He truly

believed that he had developed THE BEST

Maple bat in the industry - through wood

science and engineering, there was NO OTHER

bat company that could match the

technologies that RockBats brought to the

table.

RockBats may not have been the first

company to make maple bats, but they were

the first to do it right.

2008 Season

Long story short; research was conducted

by the major leagues in 2008, and it was

confirmed that "slope-of-grain" was the way

to go for grading baseball bat blanks. AND,

it was confirmed that Maple baseball bats

are truly stronger when hit on the

flat-grain face. SO, Bat Supplier

Regulations were changed for the 2009

season to include the following

technologies:

- The "slope-of-grain" grading for

baseball bat wood was a requirement for

all manufacturers - with a maximum

allowed slope of approx. 3-degrees on

both the edge and flat-grain face. This

technology is most recognized by the ink

spot that is now on every maple (and

birch) bat in the major leagues.

- Flat-grain grain contact is now

required for ALL bat manufacturers that

are supplying the major leagues. Thus,

the 100-year-old rule-of-thumb to place

logos on the flat grain was now changed

to the edge grain for maple (and birch)

bats - to advocate flat-grain contact.

Just like in Roland's days of being a

government research scientist, it took

years of research before finally seeing

results translated into implementation by

the industry.

2009 Season

After all the new bat regulations were

adopted by the major leagues, RockBats

chose NOT to pursue certification for

supplying bats to the major leaguers in

2009. Therefore, Roland contacted

Milwaukee's professional team to conduct

independent consulting - as a wood

scientist. By grading and rating every wood

bat received by the team, this resulted in

that team having the fewest 2-piece broken

bats out of all 30 major league teams. That

year demonstrated the levels that could be

achieved for increased safety and

performance - due to the application of

wood science in the clubhouse.

2010 Season

RockBats chose to pursue certification

in 2010, and chose to ONLY work with

Milwaukee's professional team that year.

Much like Roland's scientific approach to

conducting research projects, careful steps

were taken to demonstrate the technology

that RockBats had to offer. Bat shape

re-designs specific to the player's needs,

and commitment to quality for professional

players was the goal. By mid-season, we had

12 professional players from Milwaukee's

professional team order RockBats.

On June 26th, 2010, RockBats appeared on

the front page of the

Milwaukee Journal Sentinel.

On June 29th, 2010 - 6 of 9 starters for

Milwaukee's professional team went up to

bat with a RockBat.

In the July All-Star game, Milwaukee's two

position players that were invited to the

2010 All-Star game (Ryan Braun and Corey

Hart) both used their RockBats. Corey Hart

was also invited to the HR Derby, and had a

tremendous showing in his first round

performance.

Read more about Corey Hart's Home Run Derby

performance.

Overall, a great season.

2011 Season

In 2011, RockBats visited with major

league teams during Spring Training in AZ.

Our approach was to offer an

engineering-based approach to supplying

wood bats for professional players. Swing

Weight Analysis, coupled with bat shape

design, resulted in matching bats to

professional players that offered optimum

performance. We worked with the Colorado

Rockies and by season's end, we had 10

players total who had tried RockBats - this

included players like Tulowitzki, Helton,

Giambi, Gonzalez, and others.

RockBats also grew in the international

scene - with our international

certification in place, we now have bats

used by teams and leagues in Europe and

Asia.

In the U.S., we have a growing list of

leagues and teams that are switching to

RockBats. As players learn more about wood

quality and its importance to the

performance of a wood bat - RockBats

becomes the obvious choice.

Our trend of ADVANCING the state-of-the-art

continues into 2012.

Testing

All of our RockBat models have passed one

final stage - player testing and feedback.

Even with all of the advanced processes that

we described above, we still made sure that

our bat models were tested by actual players

at all levels of play. Even our Youth bat

models were tailored toward young players who

are only used to swinging -10 aluminum. In

all cases, we were not completely satisfied

with the final design of each of our bat

models until we achieved a feedback rating of

"WOW".

Look for the INK SPOT>>>>> |

|

|

|

|

Mid Willamette Valley

Albany, Amity, Aurora, Brooks, Canby, ,

Corvallis, Coburg, Cottage Grove, Creswell,

Dallas, Dayton, Dundee, Falls City, Gates,

Gervais, Halsey, Harrisburg, Independence,

Jefferson, Junction City, Keizer, Lebanon,

Lowell, Lyons, McMinnville, Mill City, Molalla,

Newberg, Oakridge, Salem, Scio, Sheridan,

Silverton, Springfield, Stayton, St. Paul,

Sublimity, Tangerit, Veneta, Waterloo, Willamina,

Woodburn, Yamhill |

Portland and Vicinity

Banks, Barlow, Beaverton, Camas, Canby,

Clackamas, Clatskanie, Columbia City, Cornelius,

Forest Grove, Gaston, Gresham, Happy Valley,

Hillsboro, Lake Oswego, Marquam, Milwaukie,

Molalla, North Plains, Oregon City, Portland,

Rainier, Sandy, Scappoose, St. Helens, Tigard,

Troutdale, Tualatin, Vernonia, West Linn,

Wilsonville |

Southwest Washington

Cities

Aberdeen, Battle Ground, Camas, Castle Rock,

Cathlamet, Central Park, Centralia, Chehalis,

Chinook, Cosmopolis, Elma, Ilwaco, Kelso, Kalama,

Long Beach, Longview, McCleary, Montesano,

Nahcotta, Naselle, Oakville, Ocean Park, Ocean

Shores, Pe Ell, Raymond, Salkum, Seaview,

Silverlake, Skamokawa, South Bend, Tokeland,

Vancouver |

|

We

deliver

Nationwide

but

SOLD IN THE UNITED STATES ONLY

Alabama, Alaska, Arizona, Arkansas, California,

Colorado, Connecticut, Delaware, District Of

Columbia, Washington DC, Florida, Georgia,

Hawaii, Idaho, Illinois, Indiana, Iowa, Kansas,

Kentucky, Louisiana, Maine, Maryland,

Massachusetts, Michigan, Minnesota, Mississippi,

Missouri, Montana, Nebraska, Nevada, New

Hampshire, New Jersey, New Mexico, New York,

North Carolina, North Dakota, Ohio, Oklahoma,

Oregon, Pennsylvania, Rhode Island, South

Carolina, South Dakota, Tennessee, Texas, Utah,

Vermont, Virginia, Washington, West Virginia,

Wisconsin, and Wyoming Cities: Los Angeles, San

Francisco, San Jose, San Diego, Orlando Miami,

Washington, Dallas, Houston, Boston, Washington

DC, Irvine, Phoenix, Las Vegas, Omaha, New York

city, Reno, Tucson, Denver, Seattle, Tacoma,

Ventura, Southern California, San Antonio,

Sacramento, Kansas City, Richmond, Tampa bay,

Chicago, Hudson Valley, Orange County, Salt lake

City, Nashville, Pittsburg, Charlotte, Palm

Beach, Jupiter, Atlantic City, Ontario, Anaheim |

|

|

|